Guidance on Starting Garlic Processing Business

Garlic is a widely used condiment, and the market demand for processed products is stable and has great growth potential. So how to start a garlic processing business?

First, we need to determine the garlic processing direction and product type

Before starting a garlic processing business, we first need to clarify the processing direction and product type, which will determine the subsequent equipment investment, factory layout and market strategy.

1. Common types of garlic processing products

Primary processed products: including basic products such as garlic powder, garlic slices, garlic cloves, etc., the processing technology is relatively simple, suitable for start-ups

Seasoning series: ready-to-eat products such as garlic sauce and garlic seasoning oil, with large market demand

2. Factors to consider when choosing a suitable processing direction

Market demand: Investigate the demand for different garlic products in the local and target markets.

Fund budget: Primary processing requires low investment, while deep processing requires more funds.

Technical capabilities: Evaluate your own or team's technical reserves.

Raw material supply: Consider whether the local garlic variety, yield and quality are suitable for the target product.

Then comes the purchase and configuration of garlic processing equipment

According to the determined product direction, the purchase of appropriate processing equipment is the key to ensuring product quality and production efficiency.

1. List of basic processing equipment

Cleaning equipment: used to remove dirt and impurities on the surface of garlic.

Clove peeling equipment: automatic or semi-automatic garlic clove splitter and peeler to improve processing efficiency.

Cutting equipment: selected according to product requirements.

Drying equipment: used to make garlic slices and garlic powder.

2. Equipment purchase suggestions

Choose specifications according to production requirements: estimate initial production to avoid excessive idleness or insufficient production capacity of equipment.

Give priority to the quality of key equipment: if the drying equipment directly affects product quality, a brand with stable performance should be selected.

Consider scalability: choose upgradeable or modular equipment to leave room for future expansion of production.

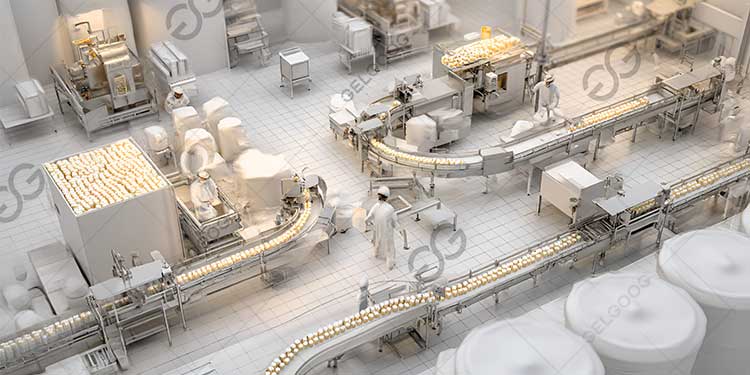

The third is factory planning and reasonable layout

Scientific and reasonable factory layout can significantly improve production efficiency and reduce operating costs.

The fourth is target market analysis and sales channel construction

Clearing the target market and establishing effective sales channels are the keys to business success.

Fifth, operation management and quality control

Good operation management and strict quality control are the basis for ensuring the long-term development of the enterprise.

Starting a garlic processing business is a systematic project that requires careful planning in every aspect, from product positioning, equipment selection, factory construction to market development. Startups are advised to start small, focus on one or two core products, gradually accumulate experience and customer resources, and then consider expanding the scale.

Leave a Reply