How Much Does A Garlic Processing Plant Cost?

In recent years, the garlic processing industry has developed rapidly, the garlic products market has continued to expand, and gradually more companies have invested in garlic processing. So how much does a garlic processing plant cost? The main costs can be considered from the following aspects:

1. Factory construction cost

Factory construction is the primary expense for establishing a garlic processing plant, mainly including:

Land purchase or rental costs: vary greatly depending on the geographical location.

Factory construction costs and basic supporting facilities: including water and electricity access, drainage system, road hardening, environmental protection facilities, etc.

2. Equipment procurement cost

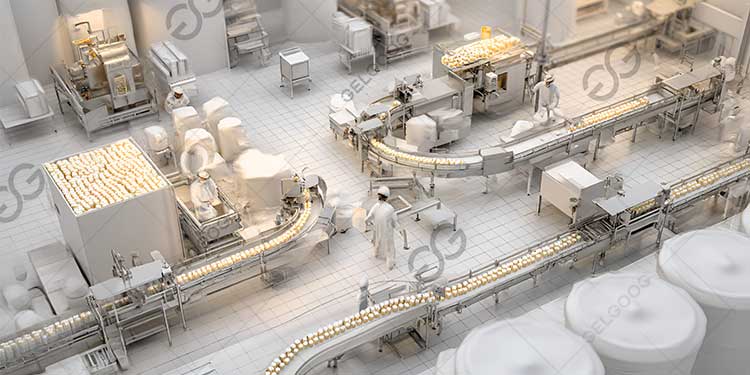

Equipment cost is the core expenditure of the processing plant, and the equipment required for different product lines varies greatly:

Products: garlic powder, garlic slices, dehydrated garlic, etc.

Main garlic processing equipment:

Cleaning machine, peeling machine, slicer/chopper, drying equipment, packaging machine

3. Raw material procurement cost

The cost of garlic raw materials is greatly affected by season, origin, and quality. In addition to procurement costs, transportation costs, storage costs, etc. must also be considered.

4. Other operating costs

Other costs include labor costs, packaging materials, promotion costs, etc.

5. Total investment estimate

Depending on the production scale and product positioning, the total investment in establishing a garlic processing plant varies greatly:

The overall cost is approximately 20,000USD-300,000USD

If you plan to start a processing business, it is recommended that you do a good market research and choose a suitable entry point based on your own financial strength. You can consider starting with primary processing and gradually developing into high value-added products.

Leave a Reply