Why Use Garlic Powder Instead of Garlic?

In modern food processing and daily cooking, garlic powder is gradually becoming an important substitute for fresh garlic. Why use garlic powder instead of garlic?

1. Storage and shelf life advantages

Fresh garlic is prone to sprouting and deterioration at room temperature, and refrigeration can easily cause moisture condensation and mold. In contrast, garlic powder is dehydrated and has a low moisture content (usually less than 8%). It can be stored for 12-24 months under sealed conditions without losing flavor.

2. Convenience of use

Garlic powder eliminates the tedious process of peeling and chopping, and can be directly added to food, making it particularly suitable for industrial food production lines and large-scale catering operations.

3. Flavor stability

The flavor of fresh garlic varies significantly depending on the origin, season and storage conditions, while garlic powder can maintain a relatively stable flavor profile through standardized processing, which is particularly important for food manufacturers who need to ensure product consistency.

4. Transportation and cost-effectiveness

The volume of garlic powder is only 1/7-1/10 of that of fresh garlic, and its weight is reduced by about 80%, which significantly reduces transportation and storage costs.

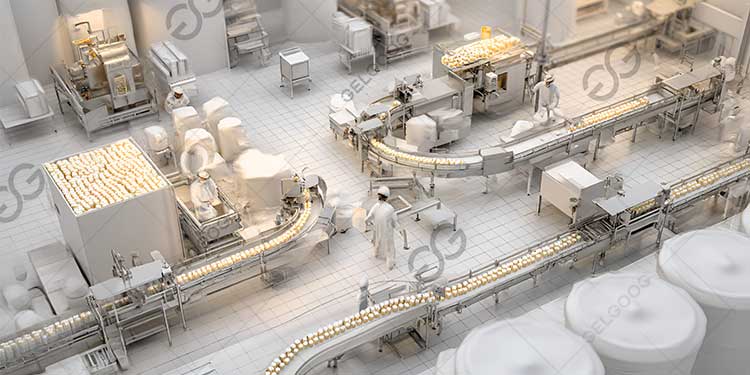

To carry out garlic powder processing business, it is necessary to establish a complete garlic powder production line. The main equipment includes:

● Garlic sorting machine: remove unqualified raw materials through vibrating screen, roller or optical sorting.

● Peeling equipment: including dry friction peeling machine and pneumatic peeling machine, the peeling rate of modern production line can reach more than 95%.

● Cleaning system: multi-stage bubble cleaning machine with ozone sterilization to ensure hygiene standards.

● Slicer: cuts garlic cloves into 1-2mm uniform slices, which affects the subsequent drying efficiency.

● Color protection tank: a pretreatment system to prevent garlic oxidation and discoloration.

● Low-temperature air drying equipment (40-60℃): retains the dryness of flavor substances.

● Crusher: equipped with a refrigeration system to prevent the temperature from rising during the crushing process.

It should be noted that with the development of food technology, modern garlic powder production pays more and more attention to energy conservation and environmental protection. Some new equipment can recycle waste heat during the drying process and reduce energy consumption by more than 30%.

Leave a Reply